|

ĆÉżËhÄá·Ú | PickÉîșŁÒșșżìQœÓî^ŁŹß@Èę(gšš)(wššn)î}ÄăÓö”œß^(guš°)á�����Łż

Subsea Connection Systems - Parker Hannifin

ÔÚ\șŁ����ĄąÉîșŁșÍłŹÉîșŁÓòÓÍâȘ(yš©ng)ÓĂÖĐŁŹßxńșÏßm”ÄÒșșżìQœÓî^ÖÁêP(gušĄn)ÖŰÒȘ�����ĄŁéÁË(shšȘ)ŹF(xiš€n)ÒșșżìQœÓî^°ČÈ«żÉżż”ÄßBœÓ��ŁŹĂÜ·â�����ĄąËźÉČć°ÎÁŠșÍČÄÁÏßxń”ÈÖT¶àÒòËŰŸùĐèżŒ]�����ĄŁ

ÔÚ±ŸÆÚ”ÄĐĄĆÉŐnÌĂ����ŁŹÎÒÌŰ”ŰéŽóŒÒŐûÀíÁËÉîșŁÒșșżìQœÓî^ßxÓĂß^(guš°)łÌÖĐłöŹF(xiš€n)”ÄÒ»Đ©ÒÉ(wššn)șÏĘ����ŁŹżìí(lšąi)żŽżŽÄăÊÇČ»ÊÇÒČgetß^(guš°)ÍŹżî(wššn)î}ĄŁ

1. ÒșșżìQœÓî^”ÄÈ(nšši)ČżșÁŠé10000 psiŁŹĐèÔÚ 3000ĂŚ”ÄÉîșŁąÆäßBœÓŁŹÔÚÆœĆ_(tšąi)ÉÏȿģKșÁŠé0 psir(shšȘ)ąÆäàé_(kšĄi)��ŁŹȘ(yš©ng)ßxÓĂÊČĂŽîĐÍ”ÄĂÜ·âŒț�ŁżÄÄ·Nźa(chšŁn)Æ·żÉÒÔMŚăß@Ó”ÄÒȘÇóŁż

ÔÚ3000ĂŚ”ÄÉîșŁÖźÖĐŁŹč€ŚśœÓî^”ÄÈ(nšši)ČżșÁŠąžßÓÚÍâČżșÁŠ(3000ĂŚ=4388 psi)5000psi���ŁŹéyówĂÜ·âÔÚßBœÓr(shšȘ)ț(hušŹ)ÊÜ”œžßËÙÁśów”Ä_ôĄŁÒòŽËŁŹËüĐèÓÉÖTÈçPEEKÖźîÔ(jišĄn)čÌ”ÄáËÜČÄÁÏÖÆłÉ���ŁŹÍŹr(shšȘ)ÀÎčÌ”ŰÒÀžœÔÚéyówÉÏĄŁ

ĆÉżËhÄá·ÚÉîș�����ŁżìQœÓî^źa(chšŁn)Æ·Ó±ŸÖДĎó¶à”(shšŽ)źa(chšŁn)Æ·ŸùČÉÓĂß@·NéyówĂÜ·â��ŁŹżÉÔÚșÁŠÏÂßM(jšŹn)ĐĐßBœÓ���ĄŁÓÉÓÚàé_(kšĄi)r(shšȘ)ÆœĆ_(tšąi)ÉÏȿģKșÁŠé0 psi��ŁŹÄúżÉßxńĆäÖĂOĐÎÈŠŒÓëpÈ(cšš)őÈŠœY(jišŠ)(gš°u)ĄąéyówĂÜ·âíȘ(yš©ng)Œ°r(shšȘ)”ÄżìQœÓî^ĄŁĆÉżËhÄá·ÚÆìÏ”ÄDSEÏ”ÁĐĆääPEEKéyówĂÜ·â�����ĄąOĐÎÈŠŒÓëpÈ(cšš)őÈŠĂÜ·âœY(jišŠ)(gš°u)�ŁŹéyówĂÜ·âíȘ(yš©ng)Œ°r(shšȘ)ŁŹĐÔr(jiš€)±ÈÒȞߥŁ

2. ÎÒÔűŚxß^(guš°)Ò»Đ©ÓĐêP(gušĄn)ÉîșŁżìQœÓî^”ÍČć°ÎÁŠ”ÄÎÄŐÂŁŹÏà±Èśœy(tšŻng)”ÄÉîșŁżìQœÓî^����ŁŹĆɿ˟a(chšŁn)Æ·”ÄČć°ÎÁŠ”œ”ŚÓжà”ÍÄŰŁż

”ÍČć°ÎÁŠżìQźa(chšŁn)Æ·żÉąČć°ÎÁŠœ””Í55Ł„�ĄŁ±ÈÈç���ŁŹ 1/2Ą±Ò(guš©)žń”Äśœy(tšŻng) DSCżìQœÓî^���ŁŹÆäČć°ÎÁŠé695 lb/1000psi����ĄŁ¶űÍŹÓé?Ą±Ò(guš©)žń”Ä”ÍČć°ÎÁŠDSLżìQœÓî^ŁŹÆäČć°ÎÁŠHé307lb/1000psi��ĄŁDSLÌæQDSCÏ”ÁĐșó���ŁŹCvÖ”ąÄ2Ìážß”œ3��ŁŹß@ÊÇĐÂĐÍżìQźa(chšŁn)Æ·§í(lšąi)”Ä(yšu)Ę(shšŹ)�ĄŁ

3. Äł(gšš)Ș(yš©ng)ÓĂßxÓĂÁË316Č»äPäČÄÙ|(zhšŹ)”ÄżìQœÓî^��ĄŁÄÇĂŽ�����ŁŹÔÚÉîșŁȘ(yš©ng)ÓĂÖĐŁŹÊÇ·ńÄÜßxńË(bišĄo)Ê(zhšłn)żìQźa(chšŁn)Æ·Ó±ŸÖĐ”Ä316Č»äPä·ÇÒçłöĐÍżìQœÓî^Łż

ÈçčûlŒțșÏßm����ŁŹ·ÇÉîșŁȘ(yš©ng)ÓÔĿìQœÓî^źa(chšŁn)Æ·żÉÓĂÓÚÉîșŁȘ(yš©ng)ÓĂ����ĄŁÍšłŁ��ŁŹĐèÒȘżŒ]”ÄÖśÒȘ(wššn)î}ÊÇÍâČżșÁŠČ»ÄÜžßÓÚÈ(nšši)ȿ而śșÁŠ500psi�ŁŹÒò?yš€n)éĂÜ·âŒțŐ곣而ś”ÄÇ°ÌálŒțéÈ(nšši)ČżșÁŠžßÓÚÍâČżșÁŠ��ĄŁ

ÔÚșÁŠÏÂßBœÓșÍàé_(kšĄi)żìQźa(chšŁn)Æ·ĄąîA(yšŽ)ÆÚÊčÓĂÛĂüÒÔŒ°ÆäËüÒòËŰÒČÒȘŒ{ÈëżŒ]·¶ú����ĄŁÈôą·ÇÉîșŁȘ(yš©ng)ÓÔĿìQźa(chšŁn)Æ·ÓĂÓÚÉîșŁȘ(yš©ng)ÓĂ�ŁŹĐĄĆÉœšŚhÄúżÉÂ(lišąn)Ï”ÎÒ”ÄäNÊÛF(tušąn)ê (dušŹ)���ŁŹŸÍŸßówȘ(yš©ng)ÓĂŚśßM(jšŹn)Ò»ČœÓŐ�ĄŁ

ÌœËśžü¶àÉîșŁżìQœÓî^œâQ·œ°ž��ŁĄ

ÔÚ\șŁ�ĄąÉîșŁșÍłŹÉîșŁÓòÓÍâȘ(yš©ng)ÓĂÖĐŁŹßxńșÏßm”ÄÒșșżìQœÓî^ÖÁêP(gušĄn)ÖŰÒȘ����ĄŁéÁË(shšȘ)ŹF(xiš€n)ÒșșżìQ°ČÈ«żÉżż”ÄßBœÓ���ŁŹĂÜ·â���ĄąËźÉî�ĄąČć°ÎÁŠșÍČÄÁÏßxń”ÈÖT¶àÒòËŰŸùĐèżŒ]�����ĄŁ

- Subsea Connection Systems - Parker Hannifin

Subsea Coupling SolutionsŁșPlate and Cartridge Mountable Stab Couplings,ROV and Diver-Mateable Connections, Related Products

Stab Style Plate Mounted Couplings

|

DSL Series couplings are designed for low separation force while under pressure. Durable PEEK or optional metal seals provide confidence for connection and disconnection at full pressure and at depths down to 3000 meters.

Features:

- Sizes 1/4 through 1-1/2 inch

- Up to 15,000 psi (1034 bar) working pressure

- Poppet valves

- Metal or PEEK primary seal, PEEK secondary seal

- Redundant sealing

- Guide sleeve option

- Welded tube stub option

Typical Applications:

- Flying lead plates

- Subsea control modules

- Subsea injection systems

- Tubing hangers |

|

DSC Series are traditional subsea couplings with PEEK seals.Redundant sealing adds a higher level of integrity to this proven design. The guide sleeve eases alignment of the coupler and nipple for a smooth connection.

Features:

- Sizes 1/4 and 1/2 inch

- Up to 15,000 psi (1034 bar) working pressure

- Poppet valves

- PEEK primary seal

- Redundant sealing

- Guide sleeve option

- Welded tube stub option

Typical Applications:

- Flying lead plates

- Subsea control modules |

|

DSE Series poppet style couplings are the most common design used in subsea applications and can be connected and disconnected at full system pressure. Typically connected and disconnected above water, their compact design is efficient and reliable.

Features:

- Sizes 1/8 through 1 inch

- Up to 10,000 psi (690 bar) working pressure

- Poppet valves

- Primary elastomer O-ring seal with back up

Typical Applications:

- Auxiliary intervention plates

- Elastomer O-ring seal is usually "make and break" topside

- Umbilical reelers |

|

DSP Series poppet style couplings are the most common design used in subsea applications and can be connected and disconnected at full system pressure. PEEK seals allow connection subsea and above water. Their compact design is efficient and reliable.

Features:

- Sizes 1/8 through 1 inch

- Up to 15,000 psi (1034 bar) working pressure

- Poppet valves

- PEEK primary seal

Typical Applications:

- Auxiliary intervention plates

- PEEK seal is suitable for topside or subsea "make and break" |

|

DST Series are unvalved, straight through couplings with unrestricted flow. Redundant interface sealing ensures reliable performance.

Features:

- Sizes 1/4, 1/2 and 3/4 inch

- Up to 8000 psi (552 bar) working pressure

- Unvalved straight through design

- O-ring/back up primary seal, secondary slipper seal

- Redundant sealing

Typical Applications:

- Connection plates where no valves are required

- Usually "make and break" topside |

|

DSB Series balanced couplings have no hydraulic separation force while under pressure. The PEEK seals are durable for connecting at full system pressure.

Features:

- Size 3/8 inch

- Up to 10,000 psi (690 bar) working pressure

- Balanced design - no separation force from pressure

- PEEK primary seal

Typical Applications:

- Subsea control modules

- Intervention systems

Stab Style Plate Mounted Couplings |

|

DSA and DSU Series poppet couplings are used in many subsea and topside applications. The ability to connect and disconnect under full system pressure, and sealing that can withstand internal and external pressure, provides secure connections for a variety of applications.

Features:

- Size 1/4 inch

- 5000 psi (345 bar) working pressure

- Poppet valves

- Back up/O-ring/back up primary seal

- Parker Nitrile O-rings standard

Typical Applications:

- Umbilical reelers

- MUX plates |

|

DSH Series couplings are used in subsea and topside RBJPlates. Typically found in hydraulic pilot applications they replace legacy couplings, pipe nipples, and fittings eliminating potential leak paths and reducing assembly time. The superior valve design of he DSH Series accomodates plate flex up to 0.100 in/2.54mm.

Features:

- Size 1/4 inch

- 6000 psi (414 bar) working pressure

- Poppet valves

- Redundant sealing

- Flow check resistant design

- Eliminates potential leak paths

- Reduces assembly time

- Parker Nitrile O-rings standard

Typical Applications:

- Umbilical reelers

- MUX plates |

|

DSF Series poppet style couplings are self-aligning allowing rigid mounting of both the male and female. High operating pressures and robust construction make them ideal for the most challenging subsea applications.

Features:

- Sizes 1/8 and 3/8 inch

- Up to 25,000 psi (1725 bar) working pressure

- Poppet valves

- PEEK primary seals

- Parker Nitrile O-rings standard

Typical Applications:

- Intervention control systems

- Subsea test trees |

|

DSM Series couplings have poppet valves and threaded sleeves. They are manually operated, diver mateable subsea connections with proven performance.

Features:

- Sizes 1/4 through 1 inch

- Up to 10,000 psi (690 bar) working pressure

- Poppet valves

- Metal primary and PEEK secondary seal

- Connect/disconnect under pressure

Typical Applications:

- Auxiliary intervention plates

- Diver mateable connections

|

|

DSS Series

Inline or Manifold Mounted Swivels

DSS Series swivels provide an unobstructed flow path force balanced design and low friction PTFE slipper seals minimize rotation torque. These features minimize pressure loss, can increase hose life and reduce fitting loosening.

Features:

- Sizes 1/2 and 1 inch

- 5000 psi (345 bar) working pressure

- Force balanced

- Full flow design

- Redundant sealing

- Low friction PTFE slipper seals

Benefits:

- Prevents hose twisting

- Reduces fitting loosening |

- Custom engineered couplings and accessories

|

Custom Engineered Products

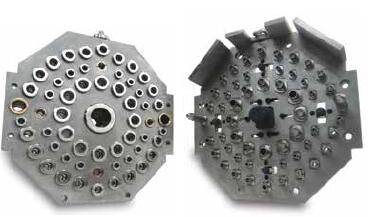

MCD Series

ROV Mateable Stab Plates

Parker's custom engineered couplings and accessories utilize proven designs to satisfy specific customer requirements and provide reliable connections that endure the demanding subsea environment.

Custom engineered solutions have included:

- Couplings mounted in ROV housing

- Cartridge mounted coupling with a self aligning nipple

- Coupling rated to 25,000 psi (1723 bar) and 160ĄăC

- Poppet style couplings in a diver-mateable plate

- Multi-coupling plates connecting over 50 fluid lines |

|

- Related Products - Offshore Topside Couplings

Other Topside Applications

ÊŻÓÍíò(qš±)ĆäÌŚÓĂżìËÙœÓî^ Top Drives

|

H & 60 Series - 316 Stainless Steel

- Corrosion resistant materials

- Quick connections allow for equipment maintenance |

|

75 Series - 316 Stainless Steel

- Durable threaded connection for large bore hoses

- Wings allow for easy operation

|

- ROVËźÆśĆäÌŚżìËÙœÓî^

|

60 Series - 316 Stainless Steel

- Proven perfomance

- ISO 7241, series B compliant |

|

71 Series - 316 Stainless Steel

- High pressure

- Flush face, low spill

|

- Other Topside ApplicationsÆäËûíò(qš±)ÔO(shšš)äĆäÌŚżìËÙœÓî^

|

1141 Series - 303 Stainless Steel & Brass

- Thread to connect

- 1/4 inch body size |

|

FS Series - 316 Stainless Steel

- Push to connect operation

- Non-spill flush valves |

|